Writer:www.firemixer.com Time:2021-09-23 11:50 Browse:℃

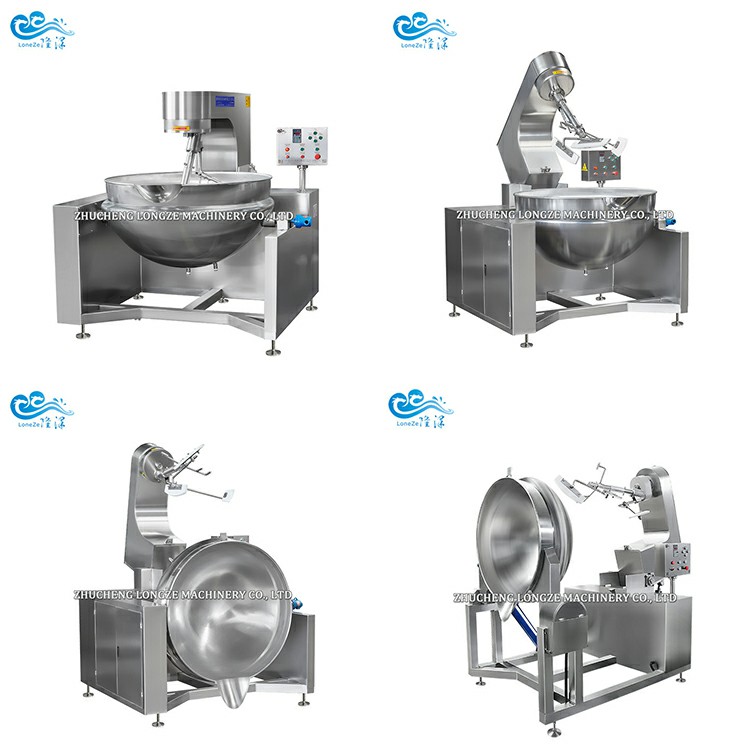

The use and characteristics of jacketed kettle

Uses and characteristics

All food-contacting parts of the steam jacketed kettle are made of 06Cr19Ni10 stainless steel, which meets the requirements of the Food Sanitation Law of the People's Republic of China. It has beautiful appearance, reasonable design, compact structure, convenient installation, simple operation, flexible use, safe and reliable, easy maintenance, etc. Features, deeply loved and praised by the majority of users.

Product structure

1. This equipment is a series of products, mainly composed of pot body, water inlet, drainage, tiltable pot and other parts.

2. The pot body is welded from the outer pot body. The inner pot body is made of 06Cr19Ni10 stainless steel, and the outer pot body is made of 06Cr19Ni10 stainless steel. According to the provisions of GB150-2011, it is tailor-welded with full penetration structure.

3. The drainage part is composed of a universal ball head.

4. The water inlet part is composed of a ball valve at the bottom of the pot.

5. The tiltable part is composed of worm gear, worm, hand wheel and bearing seat.

6. Tilting frame is composed of bearing seat, bracket, etc.

Installation and commissioning

1. When unpacking, check whether the product and accessories are consistent with the packing list. During the transportation, whether the product and parts are damaged. If there is any loss or damage, please contact our company in time to solve it.

2. The product has been tested for performance before leaving the factory, and the relative positions of all parts have been installed and adjusted. The user generally only checks it and must not disassemble it at will, so as to avoid improper reinstallation and adjustment, which will affect the performance of the product.

3. The equipment does not need to be fixed, as long as it is placed on a flat concrete floor.

4. After the equipment is in place, please assemble the spare parts according to the "installation diagram", and check whether the equipment is complete and flexible without load.

5. The power supply should meet the requirements of the mixing structure of the equipment, and the equipment casing must be well grounded to avoid leakage accidents.

6. During installation, care should be taken to ensure that the water inlet and drain pipes are unblocked, and there should be no blockage.

7. During the water delivery test of the tiltable jacketed kettle, please check whether the 4 bolts fixed by the universal joint are loose during transportation.

Operating instructions

1. Pour a small amount of clean water into the pot before feeding, brush the pot clean, put in the materials, and open the "steam valve" and "drain valve". Tilting jacketed kettle, the hand wheel can be turned to tilt the pot body for unloading. At this point, one job is completed.

2. For each operation, the "inlet valve" and "drain valve" should be opened to discharge the cooling water in the interlayer of the boiler body to ensure the normal heat exchange, so as not to extend the operating time and affect the work efficiency.

3. In order to keep it clean, it should be cleaned every time it is used.

4. Before using the tiltable jacketed kettle, check whether the rotating parts are well lubricated. Fill the oil cup with grease and inject an appropriate amount of grease into the bite of the worm gear and worm.

5. This equipment can only be used within the specified "no working pressure" range, and it is absolutely not allowed to use it under pressure, otherwise the consequences and the responsibility will be borne by the user.

Prohibited items and prohibited items Here is a summary of all the items that need to be strictly observed and prohibited items.

(1) Except those who have received education and training about the residual hazards of the machine and avoiding those hazards, please do not approach the machine.

(2) Please entrust our company to implement the transformation of machinery. Modifications, operating procedures, and changes in operating modes that are detrimental to the safety of operators or machinery may cause accidents such as injury and mechanical damage.

(3) Please regularly check whether all safety devices are functioning normally.

(4) When the safety device is found to be unable to operate normally, do not operate the machine, please notify the person in charge of management to solve it. If you can’t solve it, please contact our company.

Whatsapp/Wechat: +8615621793520

Phone: +8615621793520

qq: 3206879011

Email: Raymond@loneze.com

Add: No.215, Zhanqian Street, Zhucheng City, Weifang City, Shandong Province, China