Writer:www.firemixer.com Time:2021-08-15 14:42 Browse:℃

Planetary jacketed cooking kettle are often used in processing industries such as chili sauce, stuffing sauce manufacturers, meat products cooked food companies, condiment companies and other processing industries.

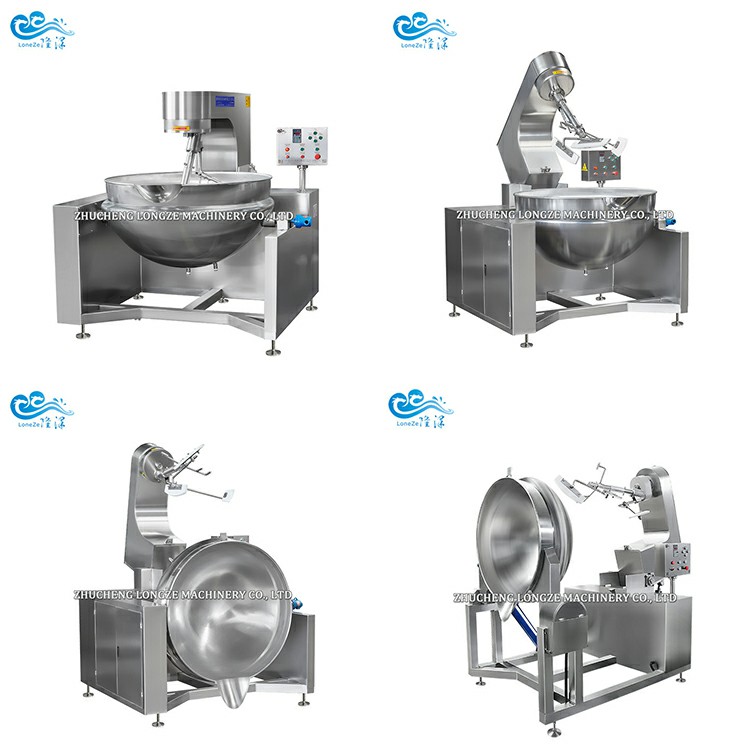

According to the different heating methods, we are also divided into various specifications and models: sauce wok, electromagnetic wok, planetary stirring wok, gas wok, steam wok, electric heating planetary wok and so on.

What is a jacketed kettle? As the name suggests, it is a pot with a sandwich in the middle of the double layer, usually composed of a pot body and legs. The pot body is a double-layer structure composed of inner and outer spherical pot bodies, and the middle interlayer is directly heated by steam/heat-conducting oil/electromagnetic coil/open flame.

The steam can be tilted jacketed kettle according to the performance of different styles are also diverse

According to the heating method, it is divided into: steam jacketed kettle, electric heating heat conduction oil jacketed kettle, electromagnetic jacketed kettle, gas (natural gas/liquefied petroleum gas) jacketed kettle

According to the different mixing methods, it can be divided into: ordinary mixing, horoscope (herringbone) mixing, planetary mixing

According to different capacity, it is divided into:

100L/200L/300L/400L/500L/600L

According to the degree of tilt, it is divided into: tiltable, vertical

The steam jacketed kettle is a device that uses back pressure to cook things. The overall working principle of the equipment is to compress the outside air, and then let the compressed air better enter the pot to increase the internal pressure, and prevent the canned cans and the lid of the equipment from jumping.

Operation precautions:

1. Before feeding into the pot, the first thing we have to do is to inject a small amount of water into the jacketed kettle, then open the ball valve at the bottom of the pot, and then open the air inlet valve of the equipment, and wait until the cold air in the jacket of the pot is found After exhausting, close the ball valve of the equipment. When the pressure displayed by the pressure gauge has reached the working pressure set by the jacketed kettle itself, adjust the safety valve to make the equipment reach the specified pressure relief value, and then perform automatic deflation operation to close the air intake. The valve stops the air supply inside the equipment.

2. Brush the inner and outer pot body of the steam jacketed kettle, then put in the material, slowly open the air inlet valve of the equipment, and when the material inside the pot body reaches the required temperature and the predetermined heating time, we must close the inlet The air valve opens the drain valve and releases the steam in the pot to keep the pressure inside the jacketed kettle at zero. Different jacketed kettles have different operations. Compared with the vertical (including vertical stirring) jacketed kettle, you can turn the handwheel on the side of the equipment. , Tilt the pot body, and then export the material.

3. Every time the equipment is operated, the drain valve must be opened to drain the condensed water inside the interlayer of the pot body. If the water in the interlayer is found to be too old, it is necessary to check whether the "steam trap drain" (trap) is malfunctioning, and whether Blocking occurs to ensure the normal progress of internal and external heat exchange, avoid causing other failures, and avoid prolonging the operation time and affecting work efficiency.

4. I guarantee the service life of the steam jacketed kettle and keep the food clean. Every time the equipment is used, it should be cleaned before and after.

Whatsapp/Wechat: +8615621793520

Phone: +8615621793520

qq: 3206879011

Email: Raymond@loneze.com

Add: No.215, Zhanqian Street, Zhucheng City, Weifang City, Shandong Province, China