Writer:www.firemixer.com Time:2021-08-01 17:24 Browse:℃

What are the applications of the jacketed kettle in the production of corn soup

Canned corn soup is processed by making canned corn, which avoids the waste of raw materials, and has simple processing technology and low cost.

Operating points Although the raw material acceptance of defective corn shoots is a defective product, shoots with serious problems such as insect moth and lignification, as well as impurities such as corn silk and bracts should also be removed, and the storage time of the raw materials should not exceed 24 hours. Rinse the dirt with clean water to further remove the filaments on the surface of the bamboo shoots.

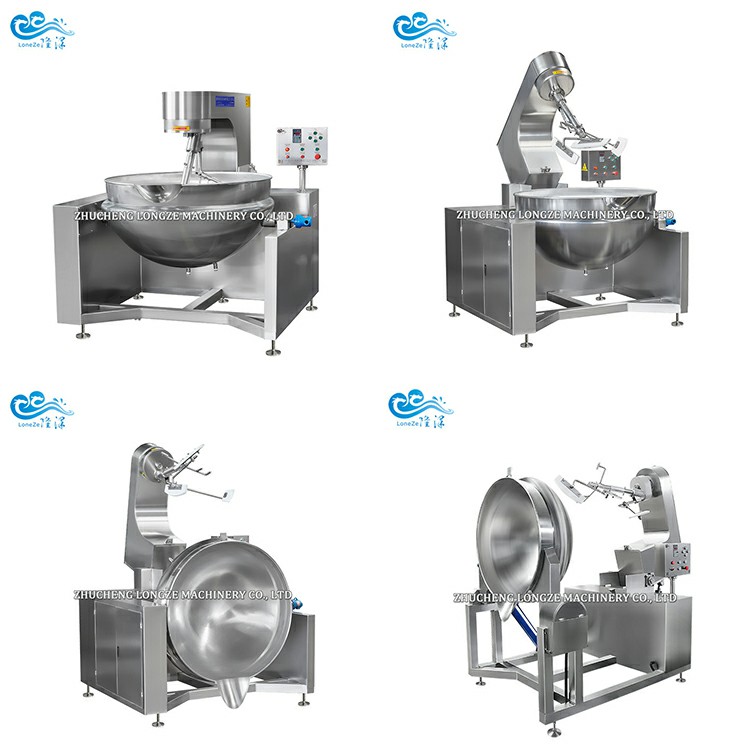

Put 100 kilograms of water into the pre-cooking industrial stainless steel jacketed kettle, add 150 grams of citric acid to make a 0.15% solution. After the water boils, put 100 kilograms of bamboo shoots in two batches into a 100 million large jacketed kettle for pre-cooking. The pre-cooking time is 5 minutes. Cooling and rinsing the pre-cooked corn shoots are immediately put into running water to cool sufficiently while removing part of the citric acid on the shoots. For crushing, cooking and blending, use a crusher to crush the bamboo shoots into rice-sized particles, and then put them into the Longze stainless steel jacketed kettle, and then add 50 kilograms of water to cook for 20 minutes. 15 kg of white granulated sugar is heated to 100°C with 15 kg of water, and filtered after the sugar is dissolved; 6 kg of starch is made into starch slurry with 10 kg of water; refined salt is melted with a small amount of hot water and filtered. During the cooking process, pour the sugar water, corn syrup, and brine into the bamboo shoot soup, and keep stirring until the cooking is over.

If you want to improve the flavor of corn soup, you can add flavor modifiers during the cooking process. When filling, venting, and sealing cans, do not use bamboo shoots to contaminate the side seal of the can, nor use tools to knock the side seal of the can to prevent the sealing quality from being affected by impurities and deformation of the can. The can is then placed in the vacuum chamber of the vacuum sealing machine for sealing. The working vacuum of the sealing machine is 0.06~0.07 MPa. After sterilization, cooling and sealing, the solid can is immediately sterilized. The sterilization formula is 10’~45’~20’/121℃, that is, the temperature will be raised to 121℃ in 10 minutes, kept at this temperature for 35 minutes, and cooled by back pressure for 20 minutes, and the temperature will drop to 40℃. Wipe the can and heat preservation inspection. Wipe dry the water on the surface of the can to prevent rust at the weld and seal of the can body. After the cans are wiped dry, they will be sent to the insulation warehouse immediately and kept at 37°C for 7 days and nights. If there is no deterioration, they can be packed into the warehouse after passing the quality inspection.

Quality standard sensory indicators Color: the milky yellow that corn soup should have; fragrance and taste: the unique fragrance of corn shoots, no peculiar smell, the taste is sweet and sour, slightly salty, and the taste is delicate; tissue state: granular viscous liquid , Allowing a very small amount of corn silk. Physical and chemical indicators: Brix ≥ 7%, sodium chloride 0.5% to 1.0%, tin ≤ 150 mg/kg, copper ≤ 5.0 mg/kg, lead ≤ 1.0 mg/kg, arsenic ≤ 0.5 mg/kg. The hygienic index meets the commercial aseptic requirements of canned food.

...

The recipe example is 100 kg of bamboo shoots, 6 kg of starch, 15 kg of white sugar, and 1.5 kg of refined salt.

...

Process Flow Corn shoots defective raw materials → acceptance → cleaning → pre-cooking → cooling → crushing → cooking → blending → filling → vacuum sealing → tank washing → sterilization → canning → insulation inspection → boxing → finished product

Whatsapp/Wechat: +8615621793520

Phone: +8615621793520

qq: 3206879011

Email: Raymond@loneze.com

Add: No.215, Zhanqian Street, Zhucheng City, Weifang City, Shandong Province, China