Writer:www.firemixer.com Time:2021-07-24 14:14 Browse:℃

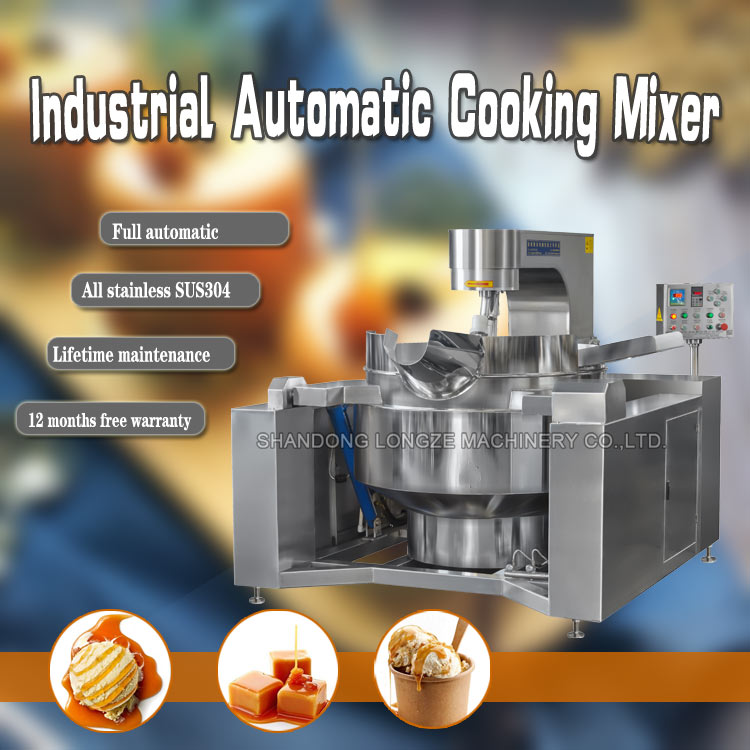

What are the heating methods for cooking mixer machines in the catering industry?

Cooking mixer machines are more common in the catering industry, so, do you know the heating method of this kind of equipment? Let's take a look at it together.

1. Heating system. Various heating forms such as steam (jacket heating (steam)), gas, electric heating, heat transfer oil, electromagnetic heating, etc. are available for customers to choose from.

2, steam. Using steam as the heat source is cheap and easy to operate. It has a large heating area, high thermal efficiency, fast heating of materials, uniform heating and easy control of heating temperature. After the heat source is turned off, the temperature in the pot can quickly drop to room temperature to avoid continuous heating and paste of materials Pot, steam heating can make the material in the pot reach 130-150℃.

3. Combustion of steam. The gas is easy to use, and the heating speed is fast, which can meet the high temperature requirements of some products, and is not limited by the factory voltage. Natural wind heating or blower heating, flame size is adjustable. The temperature rises quickly, the temperature is high, the combustion is sufficient, the thermal efficiency is high, and the pot body of the automatic cooking mixer machine is heated evenly. Compared with similar products, it can save energy by 40%. The burner is ring-shaped and surrounds the bottom of the pot. It can be heated by coal gas, liquefied gas and natural gas. It heats up quickly, can take into account the color and fragrance of the product, saves 20% energy than similar products, and is environmentally friendly and pollution-free.

Why doesn't the auto-stirring cooking mixer kettle appear mashed?

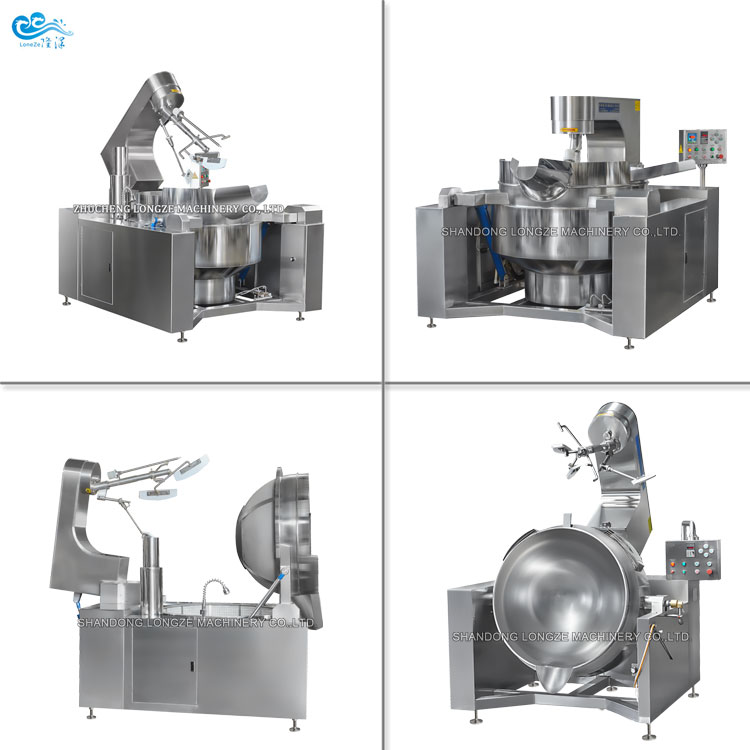

Automatic stirring cooking mixer kettle is a kind of cooking mixer kettle that can stir by itself. The stirrer of this kind of cooking mixer kettle is in full contact with the pot body, and can realize the rotation ratio of rotation and autobiography. When stirring, scrape the bottom more thoroughly to avoid the situation of mashing the pot.

The semi-automatic planetary stirring cooking mixer kettle adopts a special tilting rotation to make the planetary agitator fully contact the pot body, realize the non-integer rotation ratio of rotation and autobiography, so that there is no dead corner in the pot, and the material is stirred and mixed more uniformly. The agitator is adopted The PTFE scraper has a high degree of adhesion to the pot body, and the bottom scraping is more thorough, and the pot sticking phenomenon is not easy to occur.

Semi-automatic planetary stirring cooking mixer kettle speed regulating transmission device: The stirring shaft uses advanced rotation and sealing structure to make the pot clean and hygienic; the speed regulation adopts frequency conversion speed regulation power, and the operation is stable.

Semi-automatic planetary stirring cooking mixer kettle body turning system: hydraulic lifting method, realizes the hydraulic tilting and pouring after the stirring and the pot body are separated. It can be tilted at an angle of 90°, and the pouring has no dead ends, easy to clean, and reduces labor intensity.

Semi-automatic planetary stirring cooking mixer kettle manual: The whole pot is turned and discharged manually through a worm wheel and a worm, which is safe, stable and reliable.

The above is the main content of why the auto-stirring cooking mixer kettle does not appear to be mashed.

Whatsapp/Wechat: +8615621793520

Phone: +8615621793520

qq: 3206879011

Email: Raymond@loneze.com

Add: No.215, Zhanqian Street, Zhucheng City, Weifang City, Shandong Province, China