Writer:www.firemixer.com Time:2021-06-11 14:47 Browse:℃

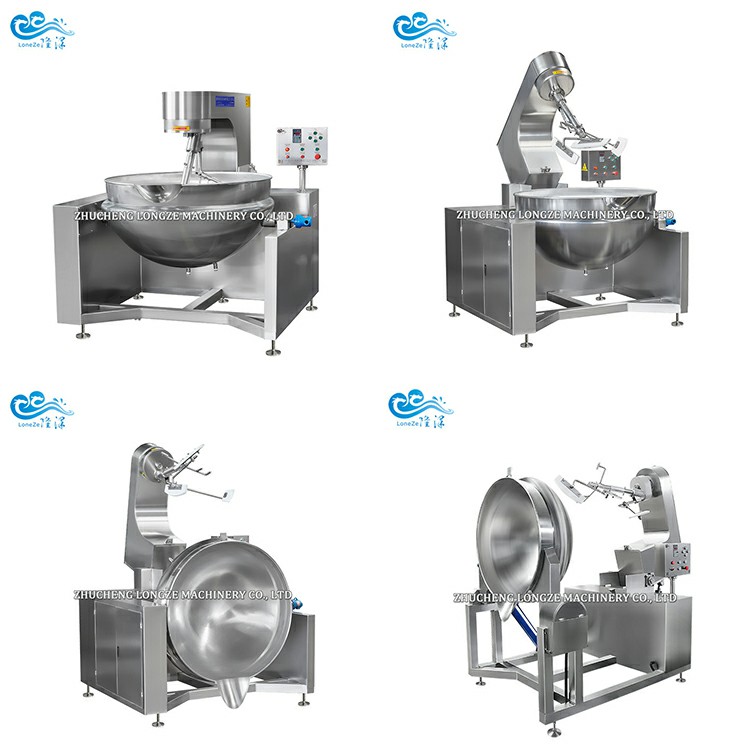

What is the difference between the three heating methods of the jacketed kettle?

Customers often ask that there are three heating methods for the jacketed kettle. Which one should I choose? I think you may not understand the difference between the three. They know the working methods of the jacketed kettle with the three heating methods and After the advantages and disadvantages, you can choose the jacketed kettle pot that suits you according to your needs.

First, let’s talk about the common points and application scope of the three kinds of jacketed kettle pots. The jacketed kettle pot is widely used in various types of food processing industry, hotels, restaurants, industrial and mining enterprises, government agencies and military units, college canteens, etc., as congee, For soup, cooking and stew. At the same time, it is also suitable for food processing and brewing, wine making, pharmaceuticals and daily chemical industries such as candy, cakes, beverages, preserves, jams, etc., as material melting, disinfection, heating, blanching, pre-cooking, preparation, cooking, sterilization, Processing such as blending and concentration is an excellent equipment for food processing to improve quality, shorten time, and improve working conditions.

The main difference is: the three heating methods are different, and the thickness of the material is different.

Steam jacketed kettle pot:

The steam produced by the boiler is passed into the jacketed boiler for heating. This type of heating is called a steam jacketed boiler.

Electric heating jacketed kettle pot:

It is called the electric heating jacketed kettle pot that heats the heat transfer oil through the electric heating tube.

Gas heating jacketed kettle pot:

The equipment is mainly composed of a pot body, a base, a burning appliance and a pot tilting device. Turn on the gas valve, ignite the gas, and manually add edible oil. When the oil temperature reaches the cooking temperature, add an appropriate amount of material, turn the pot manually, stir, so that the material is evenly heated in the pot. After the material is processed, turn off the air and turn off the flame, turn the handle, and use the worm gear and worm gear to make the pot rotate and tilt, and then pour the material into another container.

Advantages and disadvantages:

Steam jacketed boiler: The steam heating speed is fast, the first boiler is heated to boiling steam for about half an hour, but it needs an independent medium and high pressure steam system (supporting the corresponding boiler), which is expensive, and the advantage is that the heating speed is fast ;

Electric heating heat-conducting oil jacketed kettle pot: The advantage is economy, but the heating speed is slower to achieve pressureless heating, and the heating temperature can reach more than 260 degrees.

Gas heating jacketed kettle pot:

(1) Full combustion, no smoke and dust, a small amount of carbon deposit, and no environmental pollution.

(2) The flame temperature can be adjusted at will, and the temperature can be as high as about 300℃.

(3) Reasonable structure, easy to use and operate.

(4) Powerful energy saving, fierce fire, and thermal efficiency increased by about 25% compared with similar products.

(5) Fuel: liquefied petroleum gas, pipeline gas, natural gas, oil is strictly prohibited.

(6) Air consumption: about 20% lower than similar products.

The jacketed kettle pot has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of liquid material, and easy control of heating temperature. It is widely used in the preparation, dissolution, heating, cooling, heat preservation and storage of food processing and production processes.

Whatsapp/Wechat: +8615621793520

Phone: +8615621793520

qq: 3206879011

Email: Raymond@loneze.com

Add: No.215, Zhanqian Street, Zhucheng City, Weifang City, Shandong Province, China